Mitte Inquisitionem

Contactus info

-

Oratio

Paibang Industrial Zonam, Henggang oppidum, Longgang District, Shenzhen

-

Tel

-

E-mail

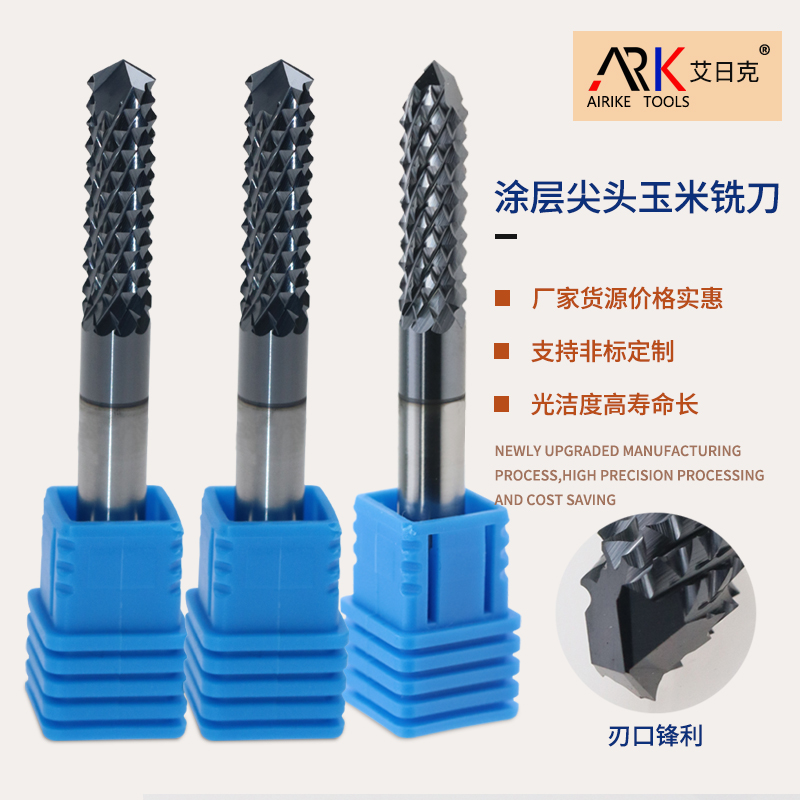

Nam inquiries Zhongyeda engraving apparatus milling Cutter, Woodworking milling Cutter, metallum Cutting Milling Cutter, misericordiam relinquam vestri email oratio nobiscum et nos adepto in tactus cum in XXIV horas.